PM2000

Production and material

follow-up system PM2000 makes it possible for manufacturing industries to

follow-up the manufacturing, material flow, warehouse levels and work in progress (WIP). By means of electronic ID-tags or

barcode labels the system registers the location and quantity of all product units or batches

in the production flow. These system functions make it possible to find out the production times, volume, status and

physical location of all products. Every machine or group of machines and all warehouse locations

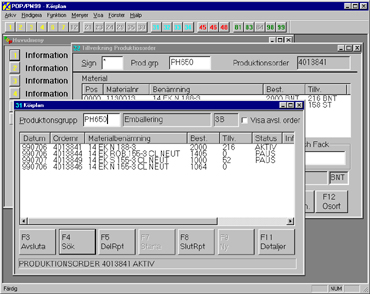

have a workstation for the registration and presentation of information, e.g. the status of a production order,

customer's order, production line etc.

PM2000's workstations are PCs with hand scanners and barcode label printers, or RFID-tag

detectors if that technology is chosen. The software is designed for

Windows and uses client/server technology. The display units' layout are adapted for

industry environment and special consideration has been taken to make it work with touch

display units, if that is wanted.

PM2000 is a complement to existing ERP-, MRP- or factory systems. The system reports data to these

systems and make use of data from them. Materials-, order-, warehouse location tables and

other dynamic system data therefore only need to be maintained in the superior system.

The display units' layout are adapted for factory environment

System requirements

- PC with 64 MByte internal memory

- Windows 95/98/NT/2000/XP

- ODBC connection to ERP- or MRP-system

- industry PC if the environment so demand

- touch display unit is optional